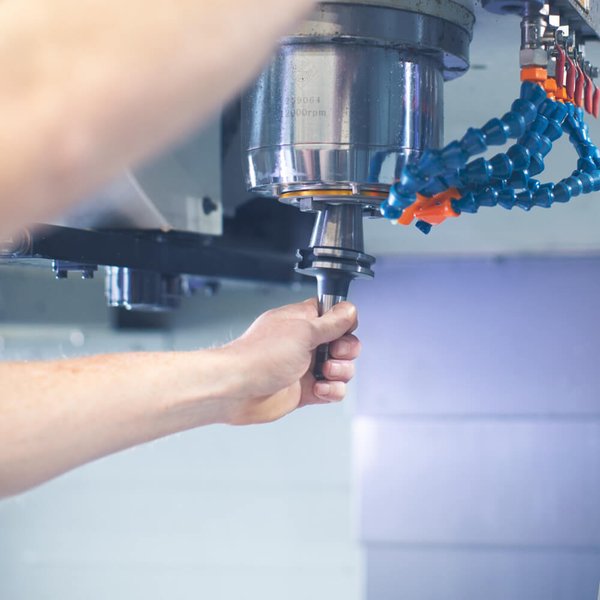

Manufacturing toolmaking

From theory to practice

Our flexibility is the decisive added value for our customers. The manufacturing offer ranges from CAD designs to the complete production of forming tools and fixtures. The combination of forming know-how and near-series production of prototypes is the key to a reliable series process.

Our experienced employees identify with your task and support you with goal-oriented and groundbreaking solutions.

We produce:

- Forming tools up to a weight of 15t and lengths up to 4,500mm. (transfer and progressive dies as well as single dies)

- Welding fixtures and assembly jigs

- Testing devices

manufacturing processes::

- 5-axis milling

- 3-axis milling

- CNC turning

- Die sinking and wire eroding

- Drilling

- Grinding

- Polishing

- Sawing

- Prototype production on different trial presses